Laser Plastic Welding

ProByLas AG develops and sells machines for high-quality welding of plastic components.

The company was founded in summer 2017. The launch of our first machine generation with laser as energy source for heating and melting the plastics, happened in autumn 2018. The founders and employees have many years of international experience in industrial plastic welding. PROBYLAS advantages:

1. Process variants and machine types that are not yet available on the market.

2. Advance innovation in industrial plastic welding and thus be able to offer our customers new solutions time and again.

Probylas website : www.probylas.com

What’s the problem?

Process Of Laser Welding

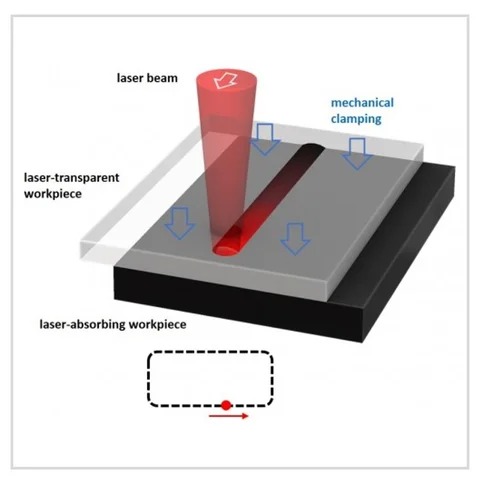

In laser plastic welding the heat to melt the plastic is introduced by a

laser directly at the weld seam. The workpieces are already pre-mounted in the final position.

The upper workpiece is transparent to the laser, so that at least some part of the laser beam can propagate to the surface of the lower workpiece.

This lower part absorbs the laser at the surface, heats up and melts.

Due to mechanical clamping pressure, the workpieces are in contact with one another.

Both the upper surface of the lower workpiece as well as the lower surface of the upper workpiece plasticize and melt.

The two melts mix to yield a strong and solid bond after cooling down.

1. Contour Welding

The Laser tracks the weld contour once. The Plastic melts only locally

SIMPLE & RELIABLE

In the contour process, the laser is focused to a spot and is moved once along the desired welding contour.

The plastic is only heated and melted over a short distance before it cools down again.

LOCAL CLAMPING

Instead of using an external clamping unit, the clamping pressure is applied by a glass ball, which rolls over the components to be welded and simultaneously serves as a focusing lens for the laser.

WELDING CIRCUMFERENCE

When welding cylindrical parts at their circumference, such as a tube with a connector, the component can be rotated in the laser beam for welding.

Alternatively, the optics can also be rotated around the stationary part.

2. Quasi-simultaneous Welding

QUASI-SIMULTANEOUS

MELT OFF AS PROCESS CONTROL

Instead of a single traverse of the welding contour, it is scanned several times per second.

The weld seam heats up gradually over its entire length and melts everywhere at the same time.

The liquefied plastic is pressed out of the weld seam by clamping pressure and the next layer of plastic continues to melt underneath.

Over time, a welding rib in the weld seam melts and a setting path becomes measurable – similar to ultrasonic or vibration welding.

3. Simultaneous Welding

A special Optics shapes the laser beam in the welding contour

IN ONE SHOT

In the contour process, the laser is focused to a spot and is moved once along the desired welding contour.

The plastic is only heated and melted over a short distance before it cools down again.

RING

Using an axicon and focusing lens, rings of different diameters and line widths can be generated from a laser beam to weld a ring contour in one shot.

CIRCUMFERENCE

The ring-shaped laser beam from the ring optics is reflected inwards by a conical mirror, so that it hits the cylindrical parts outside to inside from any direction.

The parts only have to be inserted from below into the conical mirror of the radial optics at the correct height and welded in single laser shot.

4. Mask Welding

The Mask shadows the line-shaped laser beam locally, result in welding takes places where the laser shines through the mask

QUASI-SIMULTANEOUS

MELT OFF AS PROCESS CONTROL

A line-shaped laser beam is guided over a mask with the desired welding contour. In places without coating, the laser beam reaches the joining surfaces and welds the parts.

If the laser beam hits the mask coating, it is reflected and no welding takes place in the shadow below.

In order to weld the finest possible structures, such as micro-channels, the shadow of the mask should be defined as sharply as possible. The mask is therefore placed as close as possible to the weld seam between the parts and the clamping glass. The parts have to be adjusted well enough to the mask position.

The laser welding of plastics with masks has been patented by Leister until January 2019 (some countries January 2020).