Basic and Additional Tools for Welding Improvement & Maintenance

20 & 35 kHz

Sonotrodes for 20 and 35 kHz applications (other frequencies on request) made of special high-strength materials such as aluminium, titanium alloys, steel etc..

The sonotrode deserves special attention. Optimum welding results can only be achieved with the right design and adjustment.

20 & 35 kHz

Sonotrodes for 20 and 35 kHz applications (other frequencies on request) made of special high-strength materials such as aluminium, titanium alloys, steel etc..

The sonotrode deserves special attention. Optimum welding results can only be achieved with the right design and adjustment.

20 & 35 kHz

Special composite sonotrodes with attached tips are used for large molded parts or plastics with a high amplitude requirement.

Material : Aluminium or Titanium

20 & 35khZ

Nest is fabricated from single piece material to ensure Perfect Form-Fit-Function.

Avoid stack up issue due to multiple piece

Ensure cavity is flat to the surface

Complete with side ribs to lock on Universal Platform using Clamp with T-Slot.

20 & 35khZ

Nest is fabricated from single piece material to ensure Perfect Form-Fit-Function.

Avoid stack up issue due to multiple piece

Ensure cavity is flat to the surface

Complete with side ribs to lock on Universal Platform using Clamp with T-Slot.

For material with sensitive surface, some nest area is covered with Delrin

NEST : BIG NEST WITH DELRIN (FOR PART PROTECTION)

20 & 35khZ

Nest is fabricated from single piece material to ensure Perfect Form-Fit-Function.

Avoid stack up issue due to multiple piece

Ensure cavity is flat to the surface

Complete with side ribs to lock on Universal Platform using Clamp with T-Slot.

For material with sensitive surface, some nest area is covered with Delrin

20 & 35khZ

Nest is fabricated from single piece material to ensure Perfect Form-Fit-Function.

Some part required Side pneumatic Clamp or cylinder to move the part from side to side.

Vacuum Inlet also can be design in

20 & 35khZ

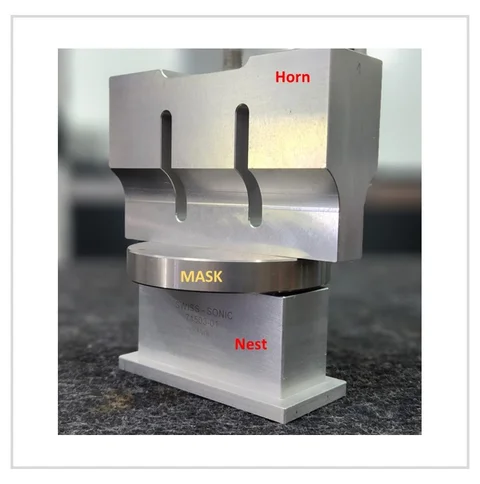

For perfect and repeatible Horn and Nest setup on the welder, Mask is highly recommended.

Mask is design together with horn and nest.

Using MASK will result in:

1, Reduce setup time (below 10 min)

2. Perfect Hon-Nest alignment

3. Minimum human dependant

20 & 35khZ

Universal Platform for Horn mounting

T-Slot for ease of Nest Clamp

4 side Single screw Levelling allow height levelling (Z) without affecting X-Y position

20 & 35khZ

XY Table

To be use for any Welder

Manual adjustment for XY position

20 & 35khZ

A : M12x1.25 to M16 x2.0

B : M12x1.50 to ½” -20

C : M12x1.25 to ½”-20

D : M12x1.50 to M12x1.50

E : ½”-20

F : M8 to M8